Oregon’s microfluidics

Tech Hub joins academic and industry partners to help small fluids make a big leap.

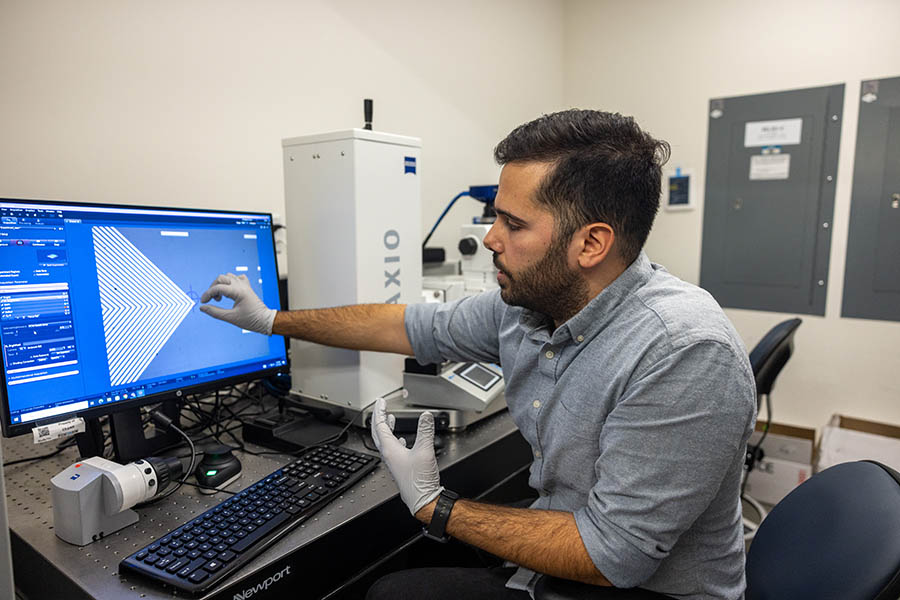

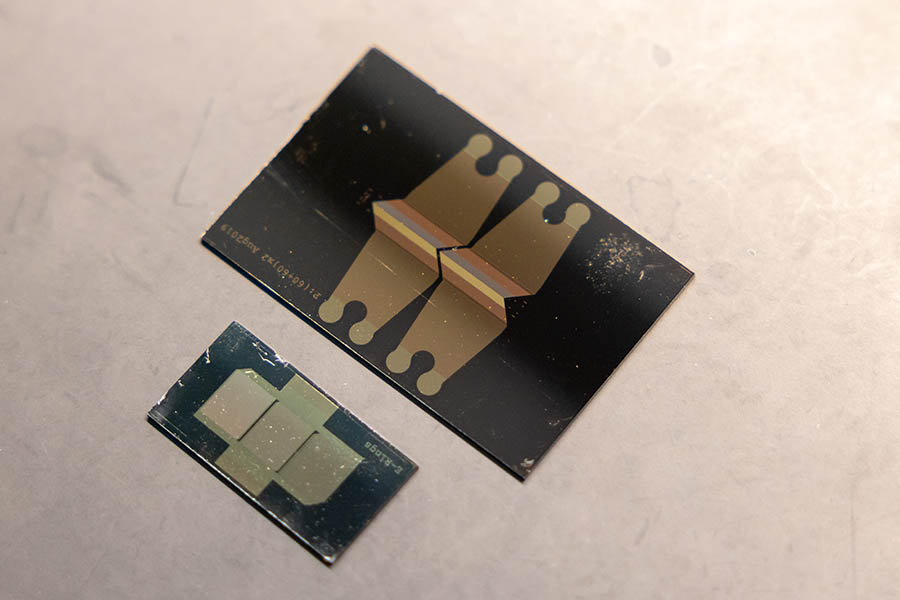

With each turn of the microscope, the tiny gray chip looked more and more like an M.C. Escher painting.

What appeared as a tiny gray speck expanded like a kaleidoscope into hundreds of honeycomb-shaped grooves and nodes, capable of delivering an electric shock to a patient’s blood cells, one which separates cancerous and non-cancerous cells for study.

Jose Luis Montoya Mira, a research engineer at Oregon Health & Science University’s Knight Cancer Institute, compared the process to un-blending a smoothie.

“When you take all the blood from patients and you analyze it all together, the result is kind of like a mess, because you have all of these cells in the blood that are different,” Montoya Mira says. “When you drink a smoothie, you say, ‘Oh, this is sweet, it has blueberry and strawberry in it,’ but you can’t actually say, ‘This is blueberry, this is strawberry.’ What we can do is separate all the ingredients into completely separate compartments, and that gives you a more granular picture of what’s going on.”

That capability is one example of microfluidics — an emerging field in which small amounts of fluid, often one quadrillionth of a liter, are placed onto a microchip through microscopic grooves, wells and channels. In health care, the technology allows for cellular study on an unprecedented level. In 2018 researchers at Oregon Health & Science University discovered the existence of “hybrid” cancer cells — cells that are a blend of tumor and blood cells, used by tumors to infiltrate, grow and adapt to a patient’s immune system — while observing ultrasounds taken from a microfluidics device co-designed by Montoya Mira. These cells, though likely used by tumors since the dawn of time, have gone undetected by humans until now.

In industry, microfluidics gives machines something they’ve always needed: cooling. The more microchips that run on top of one another in large computing devices — such as supercomputers used in data centers — the hotter they get and the greater the risk of melting becomes. Injecting liquid onto the chips allows for more to be stacked on top of one another without overheating. Microfluidics also helps in the discovery and manufacturing of specialty and industrial chemicals, many of which can be manipulated more easily at the cellular level.

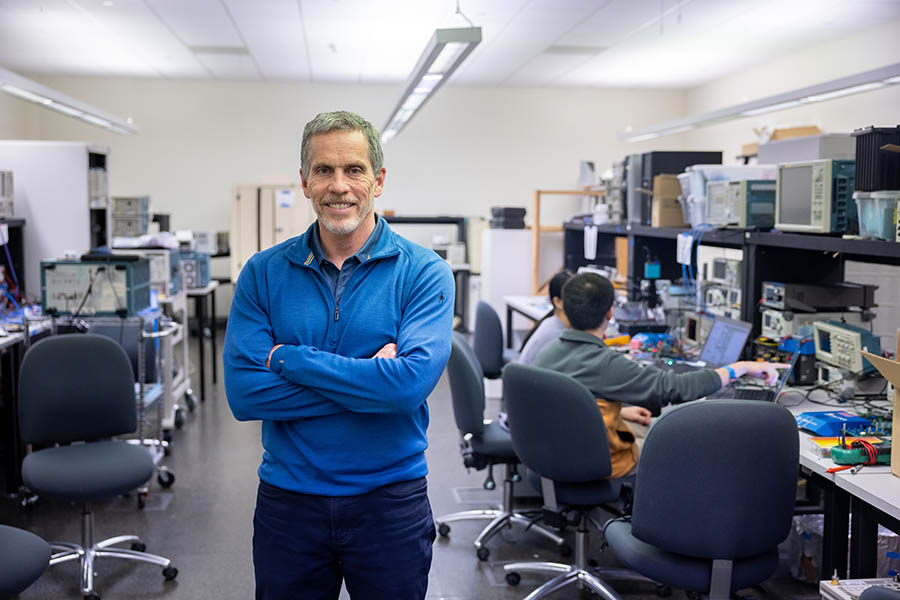

OHSU is one of 40 institutes, companies and municipalities taking part in the Corvallis Microfluidics Tech Hub, an industry coalition led by Oregon State University’s College of Engineering professor Tom Weller. In October the group was designated as a national Tech Hub by the U.S. Department of Commerce’s Economic Development Administration. The Tech Hubs Program was enacted as part of the CHIPS and Science Act in 2022. The goal of the tech hubs is to drive job creation and increase American competitiveness, all while bringing laboratory technologies like microfluidics to commercial scale.

After a four-month application process, which ends Feb. 29, between five and eight of the 32 nationally recognized tech hubs will receive awards between $40 million and $70 million to grow and scale their respective industries. The microfluidics collation was one of two Oregon institutions to receive the designation, along with the Pacific Northwest Mass Timber Tech Hub, which is also led by an OSU team.

Even though the odds of getting chosen from the federal investment are statistically low, the program is authorized to distribute $10 billion to tech hubs over the next five years, meaning this won’t be the only opportunity.

But Weller says Corvallis Microfluidics Tech Hub (or “CorMic” Tech Hub, as he and some other members call it) has reason to stand out from the competition. A 2022 industry forecast by Straits Research estimated the global microfluidics market would grow from $20.98 billion in 2022 to $117.13 billion by 2031, and from $5.28 billion in 2022 to $21.45 billion by 2032 in the United States, driven by the technology’s relevance in biological and chemical research, rising interest among manufacturers and the administration’s goals of manufacturing independence from China.

“The application of microfluidics and thermal management for the semiconductor industry is a really recent thing, which has been amplified by data centers; graphics-processing units NVIDIA, Intel and other companies are producing; and just the overall demands on computational resources. I think I heard the other day that data centers are 2% of energy consumption in the country. That certainly wasn’t the case 10 years ago,” Weller says. “And in the specialty chemical manufacturing area, a lot of that has been offshored. Most of the production is happening in Asia and other parts of the world, and that’s right at the beginning of the supply chain for the semiconductor industry. Just in the last two years, the government has realized that puts us in a very vulnerable position when we rely so heavily on materials coming in from outside of the country. Part of what the tech hub can do is enable very efficient and rapid discovery of new specialty chemicals, and that would allow us to restore a lot of that chemical-

manufacturing capability to the U.S. as well.”

Weller adds that the environmental component of microfluidics also makes it a good candidate for federal investment.

“When you have a processor that’s getting very hot, and you marry that with microfluidics technology, it can pull the heat off very effectively. It reduces the amount of energy that you use, so there are pretty significant energy savings, like 30% to 40% energy savings for data centers,” Weller says.

The goal of the CorMic hub is to create an environment where microfluidics startups and existing companies have a place to easily grow and develop manufacturing microfluidics devices into industrial-scale operations. Even though microfluidics technology has advanced significantly at the academic level, Weller and Montoya Mira say the manufacturing component still needs to catch up.

“If you look at the field of microfluidics, the complexity of the devices at the academic level versus the complexity of devices at the industrial level is quite different. The industrial-level devices are a lot simpler,” Montoya Mira says. “If you’re in the lab and 60% of your chips work perfectly, great. That’s perfect. But if 60% is what you’re getting when you’re a company, that’s really, really bad. You need it to be a reproducible science, because if you’re not 100% perfect, your customer is going to get mad at you, they’re not going to buy your devices and they’ll try to trash your company.”

“There’s a big difference between making 10 of something and 10,000 of something,” Weller says.

To address the question of scalability, the CorMic Hub enables companies to access a business that has been producing single-cell microfluidics at the industrial scale for decades. One of the linchpins of the project is the involvement of Hewlett-Packard. The Corvallis-based printing and software company has been producing microfluidics devices for its inkjet printers at scale since it debuted the ThinkJet printer in 1984.

“HP is a world leader in manufacturing microfluidics, and they’ve only just recently started to use that same technology for biomedical printers. They do single-cell dispensing on their print systems and they also use it for additive manufacturing, so they have leveraged that technology substantially in different industries. Now that they’re with the tech hub, they’re making that open to outside users to come in and use it for newer applications,” Weller says. “Essentially, HP will be potentially manufacturing for people, but they don’t have to be the ones who are always creating new products. They’re using the technology of other people.”

HP first developed microscopic inkjet printing when an engineer was testing the response of a thin silicon-based film to electrical stimulation. When electricity heated the silicon, the droplets of fluid lying under the film were expelled. Large, industrial inkjet printers, which printed by dropping thousands of tiny droplets on a sign or billboard all at once, already existed, but the discovery allowed HP to miniaturize the system — and become an early adopter of microfluidics technology.

Paul Benning, the chief technologist for HP 3D Printing, says the company’s experience manufacturing microfluidics chips at scale is what they hope to share with burgeoning businesses trying to use microfluidics in other disciplines.

“Every inkjet print cartridge that you get, on the business end of one of those is a silicon chip that has everything from transistors to microfluidic channels to control features with analog and digital circuitry. It’s really those five capabilities, and for the ability to build and manufacture microfluidic devices at volume, that we are bringing to the tech hub to pursue chip cooling and biotech applications,” says Benning.

Benning says HP is the “center of the universe” for microfluidics technology, and that the company is already branching into other applications beyond inkjet printing.

“We’ve already branched out into single-cell isolation in life science and medical research, 3D printing, additive manufacturing, that’s leveraging some of the inkjet printing capabilities. And we’ve started a development effort around chip cooling, and those are all elements of the tech hub,” Benning says. “It’s really a way to invite small companies, startups and other interested parties to come and access infrastructure, and also the expertise, the people and capabilities that have been built up around that.”

Skip Newberry, president of the Technology Association of Oregon, another member of the CorMic Hub, says the team assembled for the microfluidics hub, as well as Oregon’s talent pool, makes it a lucrative option for companies looking to commercialize the technology.

“In terms of the project team, we have a mix of larger players like HP, NVIDIA and Intel. We have some of the largest players in semiconductors and microfluidics, so if I’m looking for strategic partners and go-to-market partners, those are some of the more interesting ones that any company could want to be with,” says Newberry, who adds that recent developments and partnerships between academia and industry have helped set the stage for the CorMic Hub to be successful. “There’s a sort of confluence of things that I think are pretty exciting: One of them is the recent investment by the CEO of NVIDIA to OSU for a high-performance computing or supercomputing center. From a workforce standpoint, there was really interesting data that the State of Oregon shared during a presentation that I was involved with back in November. It showed the percentage of semiconductor R&D talent that is located in Oregon compared to the next 10 states that have a high concentration of semiconductor workforce, and in Oregon, the percentage was essentially greater than all the other 10 states combined. So that underscores the fact that Oregon is really a leader globally when it comes to a base of talent; a concentration of talent that is doing really critical semiconductor R&D work.”

Weller says federal funding from the CHIPS and Science Act would grant the tech hub the resources to grow dozens of companies and create thousands of jobs in the rural areas between Eugene and Salem, where he says the EDA wants to see job growth. Since the primary focus of the tech hubs program is to drive job creation, the tech hub is already partnering with community colleges and the Oregon Workforce Partnership to be able to staff new microfluidics companies. He says the industry requires people with two-year degrees at the technician level all the way up to Ph.D.s focused on research and development.

“We’re also trying to create a pipeline by engaging in some K-12 activities as well,” says Weller.

Even if the CorMic Hub isn’t selected for the first round of EDA funding, Weller says the collaborations made possible by the tech hub will continue, that more grant opportunities will eventually be available and that the partnerships will continue well after the application deadline closes.

For Montoya Mira, the practical applications of microfluidics technology are still being discovered. He says his cancer-screening device could potentially be used to detect any type of cell and could help in the screening of Alzheimer’s and other metabolic conditions. He says the industrial side of microfluidics manufacturing is still waiting to be developed, but when it comes to microfluidics in chips, he can already see the potential benefits of continuing collaboration.

“A lot of our [microfluidics] devices, underneath the devices, we have exactly the same cooling system that has been done in all these other devices that need that cooling. So we use the same technique on our technologies for our benefit,” says Montoya Mira. “There is not a single center or specialist, no single person who can have all the know-how and all the ideas of how to take the microfluidic field to the next level, so it’s a community push. There is more that has to happen than can happen in one single lab.”

Click here to subscribe to Oregon Business.