Strawberries and low-cost energy, two abundant Oregon resources, prompted Oregon Freeze Dry to set up shop in Albany in 1963.

Strawberries and low-cost energy, two abundant Oregon resources, prompted Oregon Freeze Dry to set up shop in Albany in 1963.

|

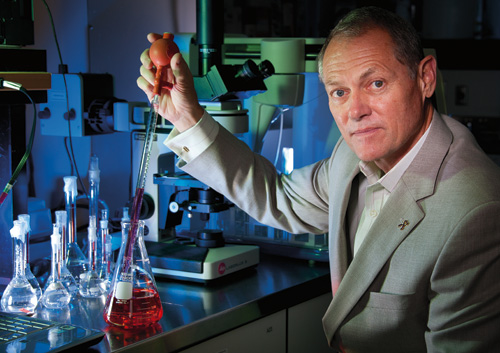

Jim Merryman, president and COO of Oregon Freeze Dry in Albany.// Photo by Adam Bacher |

Strawberries and low-cost energy, two abundant Oregon resources, prompted Oregon Freeze Dry to set up shop in Albany in 1963. The food processor was founded as a supplier of strawberries for Post Toasties Corn Flakes, says president and COO Jim Merryman. When the cereal brand failed, Oregon Freeze Dry realized “Vietnam was going on heavy,” Merryman says.

So the company went into the military-ration business, landing its first contract in 1967 with the federal government for 4 million pouches of food. Postwar, returning troops were still hungry for the product, a demand that led to the birth of Mountain House, the company’s pioneering backpacking brand. “We created the whole market segment,” Merryman says. “At one point, we were 100% of the market; 40 years later, we’re 75% of it.”

Staying true to a core product while exploiting new market niches has been a hallmark of Oregon Freeze Dry, a food processor with five business units: the government and backpacking divisions, private-label products for companies such as NutriSystem, industrial ingredients for other food processors, and freeze-dried pharmaceuticals. “We have worked hard to make sure we have many legs to our stool,” Merryman says.

But that diversification has come at a cost: The company occasionally has “shorted” its own brands in favor of supplying other companies. A 38-year company veteran who became president in 2011, Merryman plans to devote more resources to house-branded food products. The company also is expanding its pharmaceutical division, a new direction manifest in a 12,000-square-foot pharmaceutical research building in Albany that will break ground later this year.

“My strategy is for OFD to be a branded freeze-dry food company and a branded freeze-dry pharma services company,” Merryman says. “Then, with any ‘leftover’ capacity, we will supply other customers.”

The self-described largest diversified food freeze-dryer in the world, Oregon Freeze Dry grosses more than $100 million annually and employs 350 full-time and 200 part-time employees in its Albany administration, research and production facilities. A European joint venture employs another 75 in Denmark and England.

|

// Photo by Adam Bacher |

Several industry and economic trends are helping sustain and grow the company. Uncertainty — social, economic or political — apparently is a positive indicator for the food-processing industry. “We watch gold, guns and grocery,” Merryman says. “If those things are going up, that means there’s turmoil out there and that means people are buying food.” Mountain House has experienced double-digit growth annually for the past three years, and OFD has experienced companywide growth since 2009.

A growing nationwide preoccupation with emergency preparedness is another angst-driven market booster. “It could be a tornado, it could be a hurricane, but people are concerned,” Merryman says, and they want nutritious food that doesn’t require electricity if the power goes out. OFD also is capitalizing on interest in healthy convenience food by test-marketing its own freeze-dried meals — beef stew, lasagna — for everyday family use. At the same time, the company intends to invest more heavily in Mountain House, focusing in part on new ways of meeting backpackers’ twin objectives: more protein and less weight.

In the 21st century, freeze-dried isn’t just for food anymore. A market leader in freeze-dry technology, OFD has dabbled in a wide variety of products in the past decade, including nanoparticles, rocket fuel and probiotics. One of the biggest growth areas is pharmaceuticals, Merryman says. “We see a lot of products that have been patented over the years that are coming off of patent looking for a new delivery system.” More specifically, OFD will focus on alternatives to drug injections, including oral delivery, a method that will be further developed at the new manufacturing facility.

Scheduled to be completed in 2013, the pharmaceutical plant reflects the company’s desire to grow locally, a community-based philosophy that dates to 1986. That’s when a group of employees including Merryman purchased OFD, which had transitioned through two owners, 7UP and Philip Morris. Today OFD’s strategic focus on core house-branded products is another example of the company’s locally grown priorities. Not that the food processor is trading diversification for the monotony that sometimes plagues other food producers.

“I have a lot of friends in the food business,” says Merryman, who got his start at OFD scrubbing floors in 1974. “When you’re running corn, you’re running corn, and when you’re running beans, you’re running beans. We make over 450 products, and every day is something new and different.”

Linda Baker is the managing editor of Oregon Business. She can be reached at [email protected].